Closed Pigging System

Closed pigging technology has been used successfully in many areas such as the mineral oil, pharmaceutical, food, paint, cosmetics and chemical industries. The decision to use a pigging system is always based on sound reasons of economy; safety standards and environmental production certainly also have a large part to play.

In principle, every pumpable product such as powder, granule and similar substances can be pigged fully automatically, for example lye, solvent, paint, oil, liquid resin, sludge… the list is endless. Because of this, closed pigging systems are being developed for pumping more and more new substances and for increasingly higher-performance systems.

Pig Stations

Pig Launching and Receiving Stations

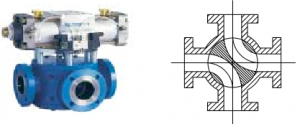

T-ring Valve T 09

The T-ring valve has three functions: Piggable Tee piece, product isolation valve and pig stop. It is possible to use it as a single station or as a part of a manifold assembly. The T-ring valve is operated automatically. Its straight passage can be pigged pocket free when the valve is closed. The T-branch is opened by the sliding ring that also serves as pig catcher. Moreover, contamination is avoided by a spring-balanced seal design.

Available diameters: DN 25 – DN 150 (1”-6”)

T-piece T 10

The T-piece is piggable in the straight passage. During the pigging process the special T-branch is completely sealed by the lips of the pig. The station can also be equipped with a pig stop that serves as a buffer for one and two pig systems. The T-piece is a welded station, especially suitable for non-standard designs, inner diameters, heating jackets etc.

Available diameters: DN 25 – DM 350 (1”–14”)

T-piece as pig launching and receiving station T 10.3

This pig station is applicable for one and two pig systems. It can be operated both manually or automatically. It is equipped with a pig stop insert that catches the pig. This insert can be removed for pig change. Sockets for propellant as well as electrical and manual pig sensing can be installed individually. A pig retainer can be mounted to avoid the pig being pulled out of its position due to product turbulences.

Available diameters: DN 25 – DN 350 (1”-14”)

T-Port Valve T 40

The T-Port valve is particularly suitable for single direction pigging systems. For such applications the T-Port valve provides safe and clean pigging results comparable with two pig systems, but with reduced control system expenditure: with only two positions it is possible to open the T-Branch and transfer the product with minimal pressure drop and stopping the pig. In this position the pipe behind the T-Port valve is isolated. In the second position the pig passage is opened, and the T-Branch is isolated.

The sealing principle utilised in the T-Port valve is the same as our proven T 41 Three-way valve. The main seal is manufactured from PTFE and covers the valve drum completely. Hence, no product residue remains in the piggable passage.

Available diameters: DN 25 – DN 300 (1”-12”)

Pig Loading and Unloading Stations

Pig loading and unloading station T 29

With this station, pigs can be safely removed from or loaded into the system. On the loading/unloading side it is equipped with sliding couplings (male and female part) which facilitates a quick and safe unloading. After opening, the pig can easily be removed from the oversized section of the station. To avoid an unauthorised opening of the station if can be locked mechanically or pneumatically. The pipeline side can be equipped either with a flange or a female sliding coupling. This station is recommended for safety reasons.

Available diameters: DN 25 – DN 350 (2”-14”)

Pig loading and unloading station T 39

With this station, the loading and unloading of pig from a pipe system will be easy, fast and safe. A part of the station can be swivelled out of the pipeline. Thus, a pressure free loading or unloading of the pig is secured. Therefore, the process of pig exchange is made easier and operational errors are avoided.

The pipeline side can be equipped either with a flange or a female sliding coupling. This station is recommended due to safety reasons.

Available diameters: DN25 - DN 150 (2”-6”)

Distribution / Manifolds

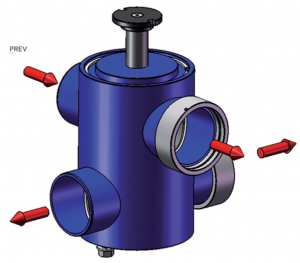

Three-way Valve

This valve facilitates the simultaneous diversion of product flows in two directions. Thus, different pipelines can be switched and pigged. The manifold can also be used as a piggable pump bypass. In this case the product flow is connected to the pump. After conveying the piggable pump bypass is switched on. Its integrated cylinder is pocket free due to its optimum sealing and therefore it can especially be used for products that allow no or only minimum contamination. The valve can be switched either manually or automatically. There is no overlapping while switching since all outlets are blocked. In combination with a pig stop insert and a pig sensor, the T 08 can also be used for launching and receiving of a pig. Thus, the pig can be reversed into another pipeline.

Available diameters: DN 50 – DN 125 (2”-5”)

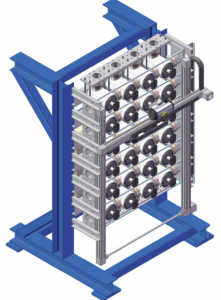

Piggable Manifold T 56

For piggable connections between different plant areas.

The manifold consists of single T40.2 valve units. The piggable connections of the T40.2 are arranged offset by 90° in two levels.

The connection of the "cross points" is achieved by turning the cylinder by 90°. The single valve units are connected to each other with sliding sleeves to the complete manifold. The valve units can easily be detached.

Thus, easy installation and disassembly are provided. Moreover, thermal expansions are compensated – especially in case of different product temperatures.

With the flexible principle it is also possible to install or remove adjust pieces or spool pieces for easy upgrades. Moreover, with the piggable manifold T 56 connections between different diameters are possible. From the upper line of the valve the product flows into the piggable lower line.

Design characteristics:

- Closed manifold system

- Piggable on two levels

- Each connection has an integrated pig stop insert

- Pigging of different diameters within a manifold system is possible.

- Compact, space saving

- Unlimited number of possible connections

- Simultaneous connection between one inlet and several outlets is possible.

- Low maintenance

- Possibility of automatic or manual operation

- Maximum reliability and protection against leakages and accidents

- Easy and quick seal replacement

- Small own weight

Full System Manifold T 57

This is the first manifold which allows pipelines of different nominal diameters to be combined in a single design (DN 50, 80 and 100). The system is closed and piggable on one side. The full system section consists of non-piggable rectangular ducts for product feed. At right angles to these ducts are the piggable pipelines which are connected at the intersection by means of a ring valve principle. This ring valve opens the connection from the product feed duct to the piggable part of the manifold and simultaneously acts as a pig receiving station. The respective ring valves are opened by a manual or pneumatic actuating unit. This actuating unit moves in parallel direction over the piggable pipeline to the required product feed full system section. This means that only one actuating unit per piggable pipeline is required. Cost effective software and interlocking devices are thus reduced to a minimum. The small shut-off unit makes the manifold very compact. All dynamic seals are exchangeable within minutes. The T 57 makes it possible to connect and distribute up to 50 feed pipelines to as many as 20 pigging pipelines in a single module. All filling and pigging processes are affected in parallels. The manifold can open and close the connections independently. Transfer pumping from tank to tank or of pigging line into pigging line is also possible with the corresponding switch processes. This unique manifold design provides a very compact and low-cost solution with minimal maintenance.

Available diameters: DN 50 – DN 100 (2”-4”)

Others on request

DDU Drum Decanting Unit

DDU Drum Decanting Unit T 65

A perfect supplement in pigging technology to provide safety and functionality when emptying drums and containers (IBC). Here, the pumped products are often used as additives for blending processes. The decanting process is semi-automated. With a pre-heated base product, the drums will be emptied almost completely. The product is decanted with a pneumatically driven lance which transports the product directly into the piggable transport line. The product will be conveyed directly to the storage tanks or into the subsequent blenders. The exact dosing of the product is measured by a weighing system that is connected to the central control unit of the DDU. A quick change-over from drum decanting to container decanting can be done with help of the flexibly designed roller conveyor. The system can be retooled for the decanting of a completely different kind of packaging within seconds.

The advantages:

- Complete discharge of high quality additives

- No product losses thanks to pigging technology

- No cross-contamination between drummed additives

- Local control system for automated filling processes

- Unique combination with pigging technology

- Products are transported directly into a piggable station.

- Traversable and piggable pipe connections to the pump.

- Minimised, non-piggable pump areas

- Piggable connection direct to blender or storage tank

Pigs

In principle, if a product can be pumped then it can also be pigged: Lube oils, aggressive chemicals, toiletries, cosmetics, pastes and foodstuffs. In special cases even granulates, powders etc., can also be pigged. We have outlined below the various pig designs available.

Duo-pig

The Duo-pig is used universally due to its form and the wide variety of elastomers it can be made from (AU, FKM, EPDM, NBR etc.). It is robust and simple to handle. Without having to take it out of the pipeline it can be rinsed in the pigging stations. The pig can be detected in the stations or in the pipeline due to its integrated magnet. For manual systems the Duo-pig can also be supplied without magnet. In this case it would be detected with manual pig locators.

Available diameters: DN 25 – DN 150 (2”-6”)

On request also up to DN 300 (12”)

Duo lip pig

Due to its flexible sealing lips, the Duo lip pig facilitates an optimum sealing. Even with inferior quality pipelines it provides excellent operation characteristics. It is also available with or without magnet. The body of this pig is manufactured from polyurethane (AU) – foamed or solid and the seal lips are non-abrasive solid polyurethane.

Available diameters: DN 50 – DN 350 (2”-14”)

Duo lip pig with replaceable lips

The I.S.T. Duo lip pig with replaceable lips is a special type of Duo lip pig that was designed especially for handling aggressive media. The advantage of this pig is that the seal lips can be replaced separately. The body of this pig is manufactured from a chemical resistant thermoplastic such as PA 6 or PVDF. The replaceable sealing lips are typically manufactured from non-abrasive polyurethane or FKM (Viton). In most cases the Duo lip pig with exchangeable lips is applied with integrated magnet.

Available diameters: DN 50 - DN 300 (2" - 12")

Jet Pig

The I.S.T. jet pig is used for pigging granulates and powders. Used regularly it prevents the formation of residual material. It can be manufactured in various elastomers such as: AU, FKM, EPDM, NBR etc. and can therefore be used universally. The jet pig is available with or without integrated magnet.

Available diameters: DN 25 - DN 150 (2" - 6")

On request also up to DN 300 (12")

Special Pigs

In addition to the above pigs I.S.T. also designs pigs for special applications. These special types (e. g. brush pigs, pigs with more sealing lips or pig forms designed for systems that outside our standard product range)

Available diameters: on request