Pipeline Hardware

Kamvalok Couplings

Kamvalok® is probably the most sold dry-disconnect coupling system in the world. It has serviced the needs of the petroleum and chemical industries for three decades and continues to grow in popularity.

The Kamvalok features a poppeted coupler and adapter that have to be connected and secured for product to flow. The unique poppet action of the Kamvalok® dry-disconnect virtually eliminates spillage of any residual liquid contained within the line after disconnection. Kamvaloks® are used at transfer points where product loss is unacceptable.

Available in 1½”, 2” and 3” sizes, in aluminium and stainless steel, the Kamvalok® offers simplicity of handling with the security of minimum loss at disconnect. Safe, reliable and affordable.

API Coupling

Couplings make fluid transfer simple and safe by connecting two shafts together. SDV Engineering supplies many types of couplings including dry-break couplings for critical applications where minimum spillage on dis-connection is vital. Applications include handling of chemical, flammable, toxic or other dangerous liquids.

Quick Connect Couplings

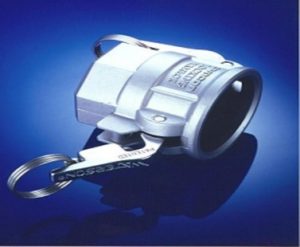

The Kamlok Coupling is the industry standard in cam and groove couplers for safety and ease of use by which all other manufacturers measure their quality. It is the original quick connect/disconnect hose coupling manufactured is designed to meet all prevailing global standards for military and civil use.

The Kamlok has unique features which set it apart from other couplings. These features (Twin-Kam™ arm design to prevent accidental release, and Spring-Ring™ to ensure proper position of finger rings for ease of operation) demonstrate commitment to excellence and an understanding of customer needs.

Autolok Coupling

The Autolok® Coupling is a high quality QC/DC locking coupling which is cleverly designed, compact and fool-proof. It allows operators to operate the unit with heavy rubber gloves on and is designed to withstand hostile environments.

Autolok® Quick Couplers are self-locking; providing an added level of safety and convenience at the fluid connection. Autolok®’s patented locking mechanism, built into the coupling arms, means the locking arms can be shut by a simple snap in one smooth motion and the coupler stays secure and shut until it is unlocked. No clips, pins or buttons.

Dry Disconnect Couplings

Dry disconnect couplings are safety components. They facilitate fast coupling and decoupling of filled hose and pipe lines under operating pressure without significant leaks or loss of the handled fluid.

Both coupling halves in the separated (decoupled) state are blocked by a sealing mechanism, so no media can escape. When coupling, both halves are initially connected with each other and tightly sealed before the sealing mechanism can be opened and a flow channel inside the coupling is enabled. Vice-versa, before separation, both coupling halves will be blocked at first, so that the flow channel is closed.

We have a whole range of special technologies for special and niche applications on hand, and would also be happy to adapt them to your individual application.

Marine Camlock Couplings

Marine Camlock Couplings are used for all types of applications including cryogenic, submersible and hydraulic operation.

Marine Camlock Camlocks are in everyday use throughout the world in marine loading and discharging terminals, ports, refineries, dock facilities, chemical plants and distribution centres.

Swivel Joint

Swivel joints are the flexible movable parts in rigid pipes. A good swivel joint will improve efficiency of movement and reduce stress and fatigue in loading arms. Swivels have a wide range of applications and are used in a wide range of industries including chemical, petroleum, petrochemical, refining, aviation, pharmaceutical, marine, food and fertilisers.

Insulating Flange

If the piping system of a marine terminal is electrically conductive, an electrical charge owes along the piping because of dock/pier-side cathodic protection systems. With the potential inductive effect of the piping system, a spark could occur at the moment when the hose is disconnected.

Insul-Flange controls undesirable electrical currents. The Insul-Flange prevents the heavy electrical ow in the piping system and eliminates the risk of an electrical arc when the hose is disconnected.

Construction: Insul-Flange is constructed of cast Nylon and is resistant to most common solvents, lubricants, hydrocarbons, esters, key tones and aqueous solutions of acids and alkalis at pH5 to pH 11. For more severe chemical service, PTFE lining is an option. Melting Point: 428°F/220°C. Elect. Resistivity: 1012 ohm/cm.

Insul-Flange retains the properties of insulating flange gasket kits, but they are much easier to install and inspect for the properties of non-conductivity.

Stainless Steel Flexible Hose

The metal braided hose is made from precision thin walled metallic strip which is formed and seam welded into a tube and then corrugated to form a flexible metal hose. We offers the ability to form the corrugations with a self-draining helical design or a more robust and flexible annular design. These corrugated hoses are available with a ¼” diameter (6mm) and larger.

These metallic hoses are usually braided to give strength when the hose is pressurized and to provide a solid protective cover during use. Multiple braid layers can increase working pressure as well as with corrugation shape, profile, wall thickness and material type. With differing engineering techniques involved and excellent burst strength-to-wall thickness ratio, these hoses are relatively lightweight compared to equivalent non-metallic hose alternatives in the market.

PTFE Flexible Hose

We provide you with a full line of Fluoropolymer hose and engineered assemblies to meet your most challenging chemical transfer application requirements. A wide range of innercore products that include smooth bore, anti-static, and heavy wall models. You can receive custom manufactured fluoropolymer hose to your specifications, delivered worldwide.

We offer engineered solutions that address flexibility, vibration, thermal or pressure related problems as well as applications involving the transfer of liquids or gases. Our fluoropolymer hose products can be found in the pharmaceutical, chemical, compressed gas, automotive and food industries.

Composite Hose

Our factory mandrel manufactured composite hoses are built with many multiple wraps of both polar and non-polar thermoplastic films that contain the fluids and vapors inside the hose wall. The barrier layer in all our standard oil and chemical hoses prevents permeation by both polar fluids (like methanol) and non-polar liquids (like gasoline) from escaping the hose. The hose wall is then reinforced with bulk woven fabrics that help protect the films in the hose wall from mechanical damage. This provides you a composite hose with superb structure and heavy duty cover layers that do not deteriorate due to ozone, UV, oil or chemical attack; that maintains maximum strength, flexibility and durability and that are compatible with the widest range of fluids and vapors.

Stainless Steel Expansion Joint

Stainless Steel Expansion Joints are normally unbraided and capable to absorb axial, lateral and angular movements while being under low or higher pressures and temperatures. Due to the construction techniques involved the bellows are relative light compared to equivalent non-metallic bellow alternatives in the market.

Stainless steel itself can withstand extreme variations in temperature ranging from very low to high temperatures i.e. from Cryogenic up to 600 °C. Stainless steel bellows are diffusion tight, have an excellent chemical resistance as well as high physical strength. On top of it, stainless steel bellows have very good corrosion characteristics. United Flexible bellows and expansion joints are generally produced and assembled in sizes from nominal 40 mm (1-1/2”) up to nominal 2000 mm (80”).

Fabric Expansion Joint

The performance of Fabric Expansion Joints for systems is determined by severity of the environment and by the selection of the materials for each component of the expansion joint. Fundamental requirements and temperature as well as chemical are important factors as well.

Fabrics are used for the reinforcement of elastomer and other coatings to yield the mechanical properties necessary to withstand the movements and pressures exerted. Insulation materials are use to reduce temperatures, optimize the performance and the life span of the elastomer or coated material in the gas seal layer. Metal Flanges are used to connect the flexible element to the ductwork. Metal flow liners are used to protect the gas seal membrane and insulation layers of the flexible element from abrasive particles.

PTFE Expansion Joint

PTFE expansion joints are flexible connectors and tremor barriers designed to compensate for misalignment, absorb expansion and contraction, and isolate vibration and shock in process piping, tanks and pumps. They also offer a low spring rate to protect stress sensitive FRP, glass or graphite equipment.

Joints are available in sizes 1/2" to 42" and from 2 to 12 convolutions for maximum movement.

PTFE expansion Joint has almost universal chemical inertness, high and low temperature resistance, invulnerability to ozone and sunlight, outstanding flex life, and low acoustical impedance (sound dampening properties).

Rubber Expansion Joint

Rubber expansion joints are designed to relieve mechanical stressors. The joints are particularly beneficial due to its flexible nature, which makes them suitable for many functions, including the absorption of sound, thermal energy and shock. Our rubber expansion joints are specifically designed to reduce the need for maintenance, repair and manual assistance.